On Friday night & Saturday, we put in about 15 hours of work on suspension parts. We also drove out to meet up with someone with a set of seats. We followed that up with playing musical cars on Sunday at the last auto-x event of the season, and some tasty sushi!

I took our aluminum front LCA, and milled out a pocket for the shock mounts. Same on the back side for the shock mount nuts. Figured they can't work ideally unless they make smooth contact. There's still a lot of material left to support the force.

I also sandblasted & deburred the assorted suspension parts, using my utility vehicle to transport them to work

Friday night we set damping to the middle setting on the Koni coilovers, and put the springs and sleeves into place.

The FFR supplied front upper arms were a little of a challenge to fit into place, as most of the brackets are a bit tight. We started with this one, and looking back, I think it was the tightest of them all. Anyway, it went together, and other areas bolted on without too much fuss!

We'll have to remove the LCA later to drill/paint/rivet some of the firewall, but we wanted to make sure everything fit. We still have the steering rack & front sway to take care of.

Rear suspension was more of the same. Spread the brackets a little, slot spacers into their home, and drop the bolts through. Spent some time looking for all the re-used donor bolts, but got things sorted with a few exceptions.

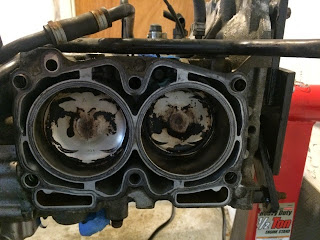

We also had to assemble the rear axles. FFR provides new shafts, onto which you slide both CV joints & housings. Messy, stinky, slippery CV grease gets everywhere. Also, the smell filled the house.. thanks, central air. Yuck!

Rinse & repeat on the other side..

We took a detour around here to go pick up the seats. Sparco Corsa, and a perfect fit for both of us, and the car too!

And we can stick wheels on it!

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)