The EJ motors have a Tumble Generator Valve that improves cold emissions, but the rest of the time is just a substantial blocked section of airflow from the intake manifold to the heads. There are a few ways to remove them, we're removing the butterfly & diverter casting, but leaving the rods, motors, and sensors in for now. It'll prevent any more complicated CELs, so we won't have trouble getting it on the road.

For reference,

EJ205: Standard 02 WRX type engine. 2.0L

EJ257: Later STi engine. 2.5L

The hybrid build uses 205 heads, 257 shortblock.

This allows for an easier mesh with the old computer system, as well as potentially improved flow relative to the 2.5L heads. You still get the improved torque of the 2.5L.

Continuing with our improvements, we bought an EJ257 oil pan, which helps retain and scavenge oil for higher reliability under high cornering Gs. The factory service manual dictates using RTV as gasket, and oh boy was the EJ205 one on there well. The previous owner must have installed it from his old engine. Spent a bit of time with a putty knife & dead blow hammer going around the outside, then gave the corner of the oil pan a few good whacks, and it came off.

We lifted it off to immediate disappointment. The previous owner had indicated a Killer B brand oil pickup was installed, as the factory oil pickups are prone to cracking, starving the engine of oil, and resulting in spun bearings. Nope. Factory. Crap.

We pretty quickly decided that this meant it was time to dig in deeper, and find out what else was missing.

The leaky side valve cover was going to be coming off anyway, so we started there. He had mentioned in person, but not in writing, that there were ARP head studs installed. Nope. Ok, time to go find the factory service manual for pulling the heads.

Yesterday morning we went down to tackle that job. Getting the cam gear/pulleys off was a bit of a pain, as the FSM specifies removing the timing belt first. We wound up using a creative routing, and a pair of vise grips to lock the cams in a safe location, then yarding on the allen bolt with a 3' breaker bar. All came off without tooo much trouble, but the first pair took quite a lot longer than the second pair. Experience, I guess.

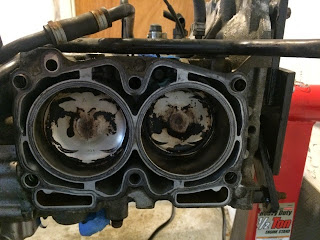

Those removed, we pulled the camshafts, keeping close track of which bolt, guide/bearing, etc belongs to each location. Next was the head bolts, which needed the 12 point sockets I'd picked up a few days ago. Heads lifted off easily after a few hammer taps. Rotate the engine stand, rinse, repeat.

We inspected the pistons, compared lots of pictures online, and determined they were OEM 257 pistons, not the JE low compression pistons that are crucial to a safe hybrid build (noticing a trend)?

Heads were also not machined to match the bore of the 2.5L block. Doesn't seem this is as crucial, but again not as advertised.

Today is a dreary sunday, so we're spending a bit of time researching parts, determining the best build options for a high-revving hybrid motor with moderate power goals. We've officially kissed our old target build cost goodbye (unless we wring some money out of the previous owner), so we're going to do it right this time, rather than running whatever we had until it popped.

If any of the readers have experience with these builds, please chime in.

.JPG)

.JPG)

.JPG)